Passive Packaging

During transport, pharmaceutical products can be exposed to too high or too low a temperature, if proper measures are not taken to prevent this. It is not always possible to have the transport take place in a fully temperature-controlled manner (for example with air freight). For small parcel shipments, road transport by temperature controlled car can be very expensive. The use of so-called passive packaging can be a solution for this, so that it is still possible to send under the correct temperature in a cost-efficient manner. CyberFreight Pharma Logistics offers various solutions and has trained people who package products in this way every day, even at its clients on site.

WHAT IS A PASSIVE PACKAGING

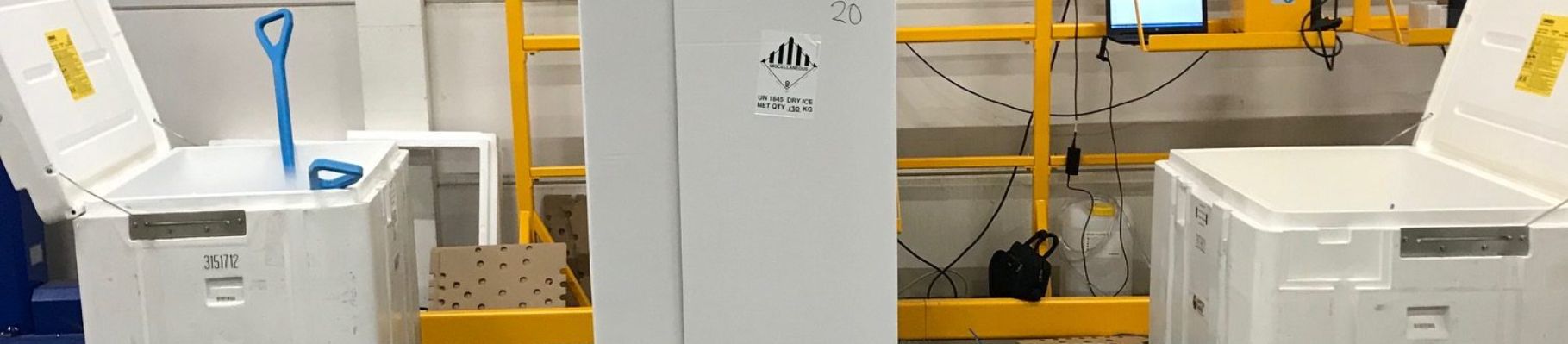

In short, passive packaging is actually a kind of cool box. The packaging ensures that the goods remain at the right temperature for a certain period of time. The solution consists of a packaging and a coolant.

Passive Packaging in a nutshell

- Various validated solutions

- Trained people to pack on customer site

- Single and multiple use packaging

TYPES OF PASSIVE PACKAGING

There are various providers of passive packaging. The packaging ranges from a very small box to pallet size and even containers. The time that the product is guaranteed to remain at the correct temperature in the packaging (the so-called validation time) depends on the specifications of the box and the type and quantity of coolant used. The validation time is usually between 48 and 120 hours. The coolants used include water, dry ice, PCM (Phase Change Material) and VIP panels (Vacuum Insulation Panels). Depending on the type of coolant used, the possible temperature range of passive packaging is between -70 and + 25 degrees Celsius.

VALIDATION AND QUALIFICATION OF PASSIVE PACKAGING

Passive packaging suppliers will first test (validate) them intensively before they are put on the market. With each packaging, a validation report is supplied by the supplier, which includes information about the performance of the packaging under different tested conditions. The user of the packaging must, before, but also during use, qualify the packaging himself and approve it for use.

USE

Most packaging is for single use, but there are also solutions that are suitable for multiple use. An additional challenge for multi-use packaging is to return the used boxes in their entirety. All CyberFreight Pharma Logistics employees who work with passive packaging are trained in all areas. They ensure that, depending on the customer’s requirements, the correct type of packaging is used and that the goods are packaged correctly. Returned packaging is also cleaned and it is also checked whether it is still suitable for reuse, before it is included in the available stock.

MONITORING

A data logger can be added to the packaging. This can be a logger that is completely in the box with the product and can be read after delivery or a “probe based” logger where the “probe” is in the box but the display with temperature reading is on the outside.